- Home

- News and Events

- Commentary

- Carbon Capture: Technology and Patent Landscape

Carbon Capture: Technology and Patent Landscape

Carbon Capture, CCS and DAC

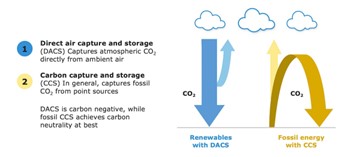

Carbon capture has come to the fore recently as a realistic tool towards net zero carbon goals. Carbon dioxide (CO₂) can be captured from fossil fuel power station flue gases or other point of origin and stored deep underground – a process referred to as Carbon Capture and Storage (CCS).

CO₂ has the useful property that it liquifies at about 1000psi. It is sufficiently heavy that this pressure is reached at about 800m depth. By pumping CO₂ down to permeable rock below 800m, it will be in liquid form and can remain there in that form if the geological conditions are right. If the CO₂ is pumped to that depth into an existing oilfield, it can have the double benefit of assisting in extraction of oil – a process referred to as Enhanced Oil Recovery (EOR).

The UK Government has set targets of 6 MtCO₂ of industrial CCS annually by 2030 and 9 MtCO₂ by 2035, and has announced four regional CCS clusters to achieve these targets. These carbon capture

projects will share up to £20bn of funding.

A related technology is Direct Air Capture (DAC). CO₂ exists in low concentration in the atmosphere (typically 0.04%). Extracting CO₂ directly from the atmosphere is not easy. Trees do it efficiently, if slowly, but new technological solutions are emerging for DAC on an industrial scale. To encourage these developments, the government has announced a £70m Direct Air Capture and Greenhouse Gas

Removals competition.

Figure 1 - Comparison of CCS and DAC, Climeworks Ltd

In the US, there are tax incentives for both CCS and DAC. The US Inflation Reduction Act, passed in August 2022, provides for carbon capture tax credits of up to $85/tCO₂ for CCS and up to $180/tCO₂ for DAC with carbon storage.

Four methods for carbon capture

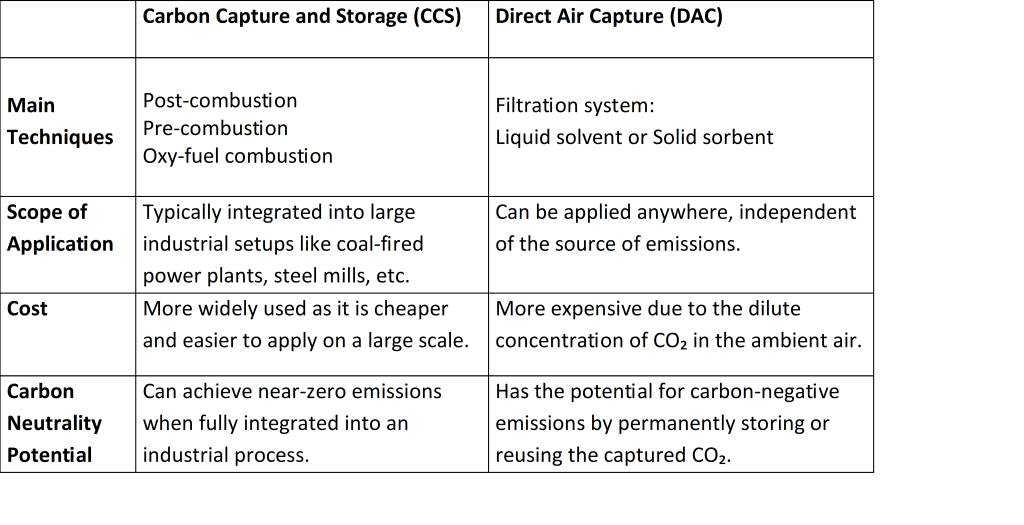

Methodologies to separate CO₂ from air and other gases to make it ready for storage or transportation generally fall into four categories: membranes, absorption, adsorption and cryogenics.1

Absorption involves scrubbing gas with a chemical (typically amine) that binds with CO₂ and releases it upon heating. For adsorption, CO₂ adheres to a solid surface, usually due to physical interactions. The membrane technique uses semi-permeable materials that selectively allow CO₂ to pass through, while blocking other gases. The cryogenic method involves cooling gases until they condense into a liquid state, which then allows for separation based on their varying boiling points. It is particularly useful for separating CO₂ from natural gas. The different methods can deliver CO₂ at different purities.

Analysis of Patent Filings

The patent records are a rich source of information, offering a window into technological advancements and industry trends.

Figure 2 Bar Chart - Comparison of Various Gas Separation Techniques in terms of number of patents (Data from US/WO/EP regions, catchwords: carbon dioxide and captur* and methods)

As shown in Figure 2, the absorption technique stands out among patent numbers, reflecting the fact that the amine process was invented in the 1930s and is today a staple process for industrial CO₂ production.2 Following absorption, adsorption emerges as the second-most patented method, and the most relevant for DAC. The cryogenic approach is energy intensive and is unsuitable for DAC. This is reflected in the patent numbers.

Role of Oil Companies in Carbon Capture

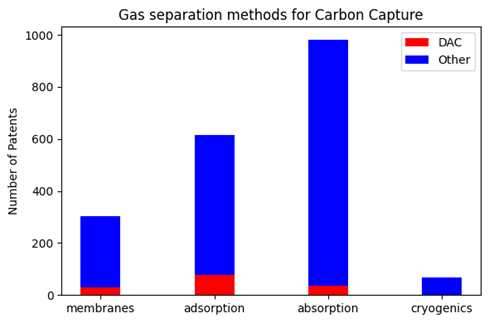

In the expansive domain of carbon capture, with its potential to mitigate environmental concerns, a diverse range of players emerge as major contributors. Analysing the top 10 patent assignees in the US/WO/EP jurisdictions, oil companies including Exxon Mobil and Saudi Arabian Oil, emerges as key players.

Figure 3 - Top 10 Assignees in the carbon capture field for general, absorption and adsorption methods.

These oil giants have a number of reasons to be interested in CCS. A first reason is that CO₂ is often a by-product of fossil fuel extraction or refining, either because it is present in a significant proportion in natural gas or because heavy petroleum products require steam reforming which produces CO₂. A second reason is because CO₂ captured from these processes may be re-used for EOR.

In EOR, the injected CO₂ acts to lower the viscosity of the oil, making it easier to pump to the surface. In the early years of EOR in the Permian Basin in West Texas, CO2 was sourced from reservoirs of natural CO2 or from natural gas processing and was pumped underground but was not expected to remain there. It would re-emerge through production wells and be re-cycled. In 2004, BP attempted a more permanent scheme and injected 3.8 million metric tonnes (3800kt) of CO₂ 1.9km below the desert in Salah, Algeria, but the project was suspended over concerns that the rock formation may not be adequately sealed.3 Nevertheless, the prospect of reusing CO₂ for deeper oil recovery is clearly of interest.

Direct Air Capture

DAC is not science fiction. Howard J Herzog of MIT wrote in 2018: 'The question for DAC is not if we can extract CO₂ from the atmosphere, but whether we can do so economically on a large scale.'4

The process of DAC can be broken down into the following steps:

- Ambient Air Intake: Large fans draw ambient air into the DAC system.

- Binding CO₂: The CO₂ in the ambient air binds to a filter material, typically a specially designed liquid solution or solid adsorbent like a Metal-Organic Framework (MOF)5. The choice of adsorbent is crucial, influencing the system's efficiency and selectivity towards CO₂.

- CO₂ Release and Collection: Once the filter material is saturated with CO₂, it undergoes a regeneration process where CO₂ is released from the filter. This is achieved by heating the materialor exposing it to a vacum. The released CO₂ is then captured and stored or utilised.

Figure 1 - Illustration of DAC Technology Process6

Can we implement DAC on a large scale without breaking the bank?

In 2021, Climeworks unveiled a 4ktpa DAC plant in Iceland, named 'Orca’ which was billed as the first industrial scale DAC plant in the world. Climeworks have since announced a 36ktpa plant named

“Mammoth”.5 The demand for EOR in the Texas Permian Basin is such that a new benchmark has been set in a 2022 announcement by 1PointFive to commence a DAC plant in that location with capacity for 500ktpa.7 At these capacities, DAC begins to make a meaningful comparison with the installed capacities of post-combustion and pre-combustion CCS plants, although it is still a drop in the ocean in the context of all carbon capture efforts and needs.8

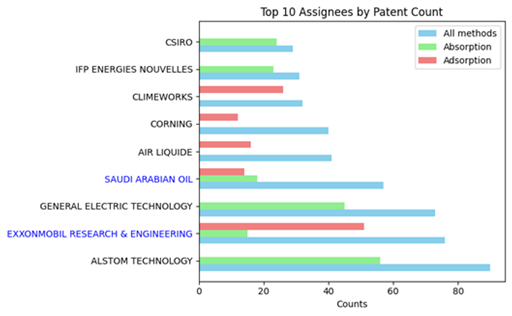

The chart below illustrates the proportional of carbon capture patent applications that encompass “direct air capture". A significant increase in patent applications referencing DAC is evident, especially after 2021.

Figure 2 - Trend Graph: Percentage of DAC Patent Applications in Relation to General Carbon Capture Patents

Patent Search Methodology

Carbon capture technologies span a wide range of patent classifications, and while there are various methods to mine the patent database for this topic, the catch words "carbon dioxide or CO₂" and "captur*" together with the CPC code Y02C-20/40 (capture or disposal of greenhouse gases, with a specific focus on CO₂) provide a comprehensive overview.

As with any modern technology, it is commonly observed that patent application numbers from China overwhelm those from other parts of the world. This dominance can sometimes overshadow trends from other regions. However, if we narrow our perspective to filings from the US/WO/EP jurisdictions, more meaningful pictures emerge.

For the precision of data analysis, the CPC code Y02C-20/40 was used. The catch word "direct air captur*" was used in combination with "carbon dioxide or CO₂" to identify DAC-specific patents. Proximity searches involving "carbon dioxide" and "captur*" give a broader dataset for generic carbon capture patents.

An auxiliary verification was conducted using the IPC class B01D-53, which revolves around gas separation. Both CPC and IPC classes showed the same trend, ensuring consistency in the derived trends. The consistency between the CPC and IPC trends reaffirms the validity of the findings and ensures that the observed patterns are not mere anomalies but indicative of a broader industry trends.

Conclusions

The patent filing data indicates a growing market for carbon capture technologies. The rate of growth is greatest in DAC patent applications. As DAC technologies mature and achieve economies of scale, they could potentially command a significant market share. However, the challenge of establishing a robust supply chain for DAC at a large scale remains9. Environmentally speaking, DAC, if widely adopted and integrated with renewable energy sources, has the potential to help reduce net carbon emissions alongside post-combustion and pre-combustion CCS techniques.

The investment in these technologies, as represented and underpinned by the filing of patent applications, gives hope for a pathway to a sustainable future, if CCS can be deployed hand-in-hand with other CO2 reduction strategies. There are, however, sceptics. In a recent TED Talk, former US Vice President Al Gore fiercely criticised enthusiasm for DAC technology, dismissing it as a mere excuse for oil companies to continue business as usual.

Author

This report was created by our 2023 Summer Intern, Jessica Shu, as an exercise in demonstrating the power of patent databases as an information resource. Jessica has an MSc in Applied Computational Science and Engineering from Imperial College London. She used OrbitTM and other databases to generate her report.

Footnotes

1Songolzadeh, M., Soleimani, M., Takht Ravanchi, M., & Songolzadeh, R. (2014). Carbon dioxide separation from flue gases: A technological review emphasizing reduction in greenhouse gas emissions.

The Scientific World Journal, 2014, 1–34. https://doi.org/10.1155/2014/828131

2“Number of patents” represents patents/patent applications published since records began and not patents currently in force. Patents generally expire after 20 years.

3Herzog, H. J. (2018) Carbon Capture (pp. 103-104). The MIT Press, Cambridge Massachusetts

4Herzog p128

5Sanz-Pérez, E. S., Murdock, C. R., Didas, S. A., & Jones, C. W. (2016). Direct capture of CO₂ from Ambient Air. Chemical Reviews, 116(19), 11840–11876. https://doi.org/10.1021/acs.chemrev.6b00173

6https://srrweb.cc.lehigh.edu/app/DAC

8According to the International Energy Agency, there are now around 40 commercial capture facilities in operation globally, with a total annual capture capacity of more than 45 Mt CO2: “Tracking Clean Energy Progress 2023” www.iea.org. This is a mere fraction of the total of 2 billion tonnes of CO2 “being removed from the Earth’s atmosphere each year” as reported by Nature, against a global need to remove a further 9.6 billlion tonnes p.a. www.nature.com 23 January 2023.

9https://climeworks.com/news/climeworks-mammoth-construction-update-mar23

Other News